General Motors Summer Job

General Motors Summer Job

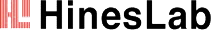

One year before graduating from North Carolina State University, Steve Hines participated in the General Motors Student-Intern Summer Program in Detroit.

The assignment:

“Design a vehicle to be used by six people for long-distance travel to allow for flexible interior use and facilitate moderate passenger activity.”

Innovations proposed by Steve, most of which are now commonplace:

- Vehicle layout, similar to a van.

- Padded baby crib behind last seat.

- Rear seat converts into a bed. Black-out curtains.

- Fold-out table between second and third row seats.

- Map-based navigational system (see below).

- Molded plastic body panels. To save weight, eliminate the cost of painting, eliminate the possibility of the panel rusting.

- Removable center console with radio/TV and refrigerated cooler. When the cooler is returned to the vehicle, it makes electrical contact to recharge its own battery, and connects to the vehicle’s speakers. The TV faces the rear-seat passengers.

- Headphone wiring is molded into the wall panels.

- Air conditioning ducts are molded into the foamed plastic walls.

- Front passenger seat can be flipped to the rear.

- No interior handle for rear hatch, so that children cannot accidentally open it.

- Closet to organize loose items.

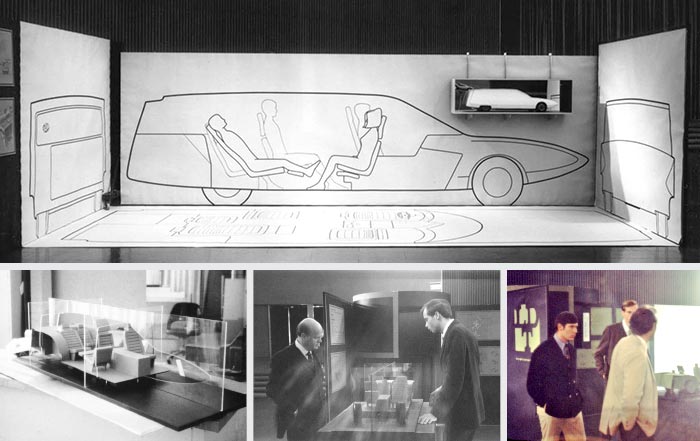

Map-based navigational system:

|

|

In this proposed system AAA would provide maps on microfiche, one fiche for the USA, and a separate fiche for each zone. The microfiche is rear projected onto a screen, and is slowly advanced and rotated on the screen as the car is driven. The driver can zoom in to see detail in the map to read streets.

The joystick and rotation controls on the front are for initial setup, to position the map to the car’s current location.

This map-based navigation system predated the 1985 Etak Navigator by 17 years, and the first GPS navigation system offered in a car (the 1995 Oldsmobile) by 27 years.

|

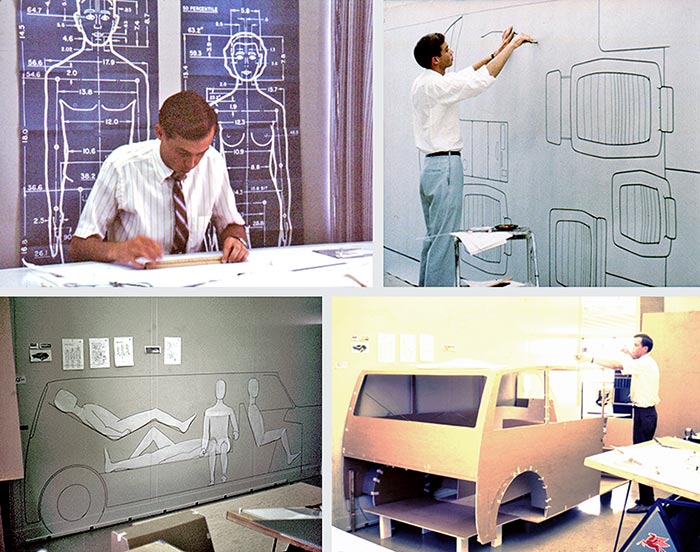

At the end of the summer, the summer interns presented their projects to Bill Mitchell, VP of Styling. The curved shape is a cylindrical drawing to show the surrounding view for the driver.

An especially fun day was near the end of the summer (too late to be fired) when another student intern, Nancy Dunker, and I paddled a “boat” made of a 4×8-ft. sheet of foamcore out on the G.M. Tech Center reflecting pond. The boat quickly folded and sank in 2-feet of water. The potato chips and Coke cans floated away, and we got soaked. The security guards were not amused, but we became instantly famous and hundreds of employees at the windows of the Styling building loved it.

No products shown here are being offered for sale, but are being shown as examples of innovation, developed by Steve Hines, which clients of HinesLab may expect on a contract basis.