Drag Reduction for Elevators

Drag Reduction for Elevators

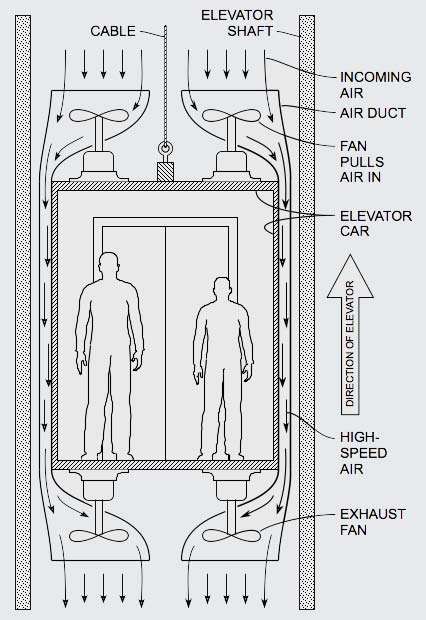

With skyscrapers being built taller, and elevators moving faster, the air in elevator shafts acts like a compression spring to resist the motion of the elevator, which adds to the load on the cables, and more electricity to power the motor. The elevator in the 108-story Shanghai Tower, in China, travels at 40 MPH.

Elevators are designed to maximize interior space, leaving very little space between the elevator and the shaft for air to rush by in the opposite direction, when the air acts like a compression spring.

This is a proposal to reduce the effect of this “air spring” by using fans to pull the air in the opposite direction, pass it through reduced-cross-section air ducts beside the car, and expel it out on the trailing end, to make the elevator aerodynamically neutral.

This is a technology announcement and license offer. Please contact Steve Hines to discuss a manufacturing license.

USA

email: Steve@HinesLab.com